Stainless Steel 904L Hex Nut Manufacturer

Home » Stainless Steel 904L Hex Nut

Stainless Steel 904L Hex Nut

UNS N08904, 1.4539, SUS 904L, ASTM A193 Stainless Steel 904L Hex Nut

ASTM A193 Stainless Steel 904L Heavy Hex Nut

UNS N08904, 1.4539, SUS 904L, ASTM A193 Stainless Steel 904L Heavy Hex Nut

ASTM A193 SS 904L Hex Nut

UNS N08904, 1.4539, SUS 904L, ASTM A193 904L SS Hex Nut

ASTM A193 Stainless Steel 904L Flange Nut

UNS N08904, 1.4539, SUS 904L, ASTM A193 Stainless Steel 904L Flange Nut

Hex Forge Inc. is a leading provider and manufacturer of martensitic Stainless Steel 904L Hex Nuts in various sizes and shapes. 904L stainless steel is an austenitic, non-stabilized grade. This type of stainless steel has a low carbon content, as indicated by the L next to the grade number. These stainless steel 904l self-lock nuts have a maximum carbon content of 0.02 percent. The low carbon concentration of these fasteners prevents intergranular corrosion by making them resistant to welding sensitization. This high alloyed stainless steel grade has copper in its alloy to improve its resistance to strong reducing acids such as sulphuric acid. The 904L Hex Nuts are also known for their exceptional formability, durability, and weldability. Because stainless steel 904l heavy hex nuts are non-magnetic, they can be employed in situations where their non-magnetic properties benefit the planned product. While fasteners made of Grade 904L stainless steels have considerable oxidation resistance, their structural stability is compromised at temperatures beyond 400°C. The alloy of 904L Stainless Steel Nuts can be solution treated between 1090 and 1175°C, after which the fastener can be quenched by rapid cooling. Stainless steel 904l flange nut must be cold worked before solution treatment to achieve the best stress corrosion cracking resistance. Despite this, grade 904L Nuts are still prone to stress-related cracking, particularly in chlorine conditions.

STAINLESS STEEL 904L HEXAGONAL NUTS MANUFACTURER, STAINLESS STEEL 904L FLANGE NUT, ASTM A193 SS 904L HEX HEAD NUT, 904L STAINLESS STEEL INDUSTRIAL HEX NUTS PRICE.

- About Stainless Steel 904L Hex Nuts

- Specification And Material Grade Of Stainless Steel 904L Hex Nuts

- Equivalent Grades Of Stainless Steel 904L Hex Nuts

- Stainless Steel 904L Hex Nut Dimension Chart

- 904L Stainless Steel Heavy Hex Nut Dimensions

- Weight Chart Of Stainless Steel 904L Hex Nuts

- Stainless Steel 904L Hex Nuts Chemical Composition

- 904L Stainless Steel Hex Nuts Mechanical Properties

- Ready Stock Of Stainless Steel 904L Hex Nuts

- People also Search for 904L SS Hex Nuts

- We Export Stainless Steel 904L Hex Nuts Across the Globe

HEXAGON STAINLESS STEEL 904L HEX NUT SUPPLIER, SS 904L EYE NUT, SS 904L SLOTTED HEX NUTS, M16 STAINLESS STEEL 904L HEX NUT STOCKIST IN MUMBAI, INDIA.

Epoxy coating, electropolishing, zinc plating, chrome, oxidation, and other finishes are available for the AISI 904L Hex Nut. The 904L Hex Nuts, like several other austenitic stainless sheets of steel, have a high oxidation resistance. However, because of the risk of structural failure above 400°C, using ss 904l Hex Nuts is not recommended at such temperatures.

Specification And Material Grade Of Stainless Steel 904L Hex Nuts

- Cold Forming process: M2-M24

- Hot Forging process: M24-M100, 1-1/2” Dia, up to 1100mm lg

- CNC Machining for M100 / 4” Dia, up to 1500mm lg

- Manufacturing M2, M3, M3.5, M4, M5, M6, M8, M10, M12, M14, M16, M18, M20, M22, M24, M27, M30, M33, M36, M42, M45, M48 to M160 and Custom Metric Stainless Steel Hex Nuts

Equivalent Grades Of Stainless Steel 904L Hex Nuts

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| SS 904L | N08904 | 1.4539 | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 | SUS 904L | 904S13 | – |

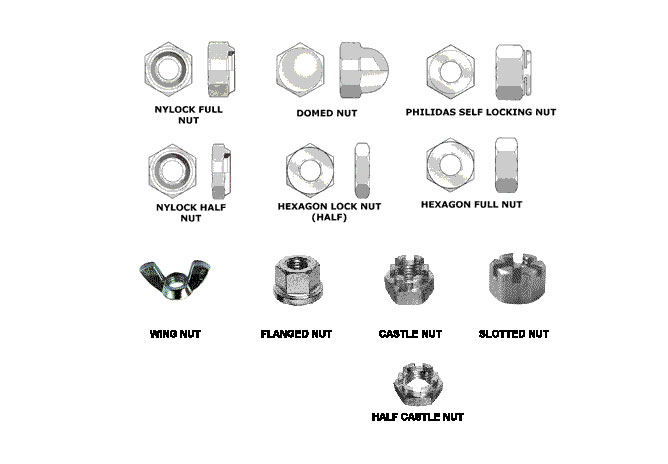

Various Types of 904L Stainless Steel Hex Nuts

SS 904L Hex Nut

- UNS N08904 Hex Nuts

- SS 904L Hex Head Nut

- ASTM A193 Stainless Steel 904L Hex Nut

- SUS 904L Hex Nut

- Stainless Steel 904L Hex Nut Manufacturer

- AISI 904L Hexagon Nuts Exporter

- Stainless Steel 904L Hex Nuts

- ASME SA193 Stainless Steel 904L Hex Nut

- 904L Stainless Hexagon Nut

- Stainless Steel 904L Hex Nut Supplier

- 1.4539 Hex Nuts

- Stainless Steel 904L Hex Nut Stockist

SS 904L Heavy Hex Nut

- SS 904L Heavy Hex Head Nut

- Stainless Steel 904L Heavy Hex Nut Manufacturer

- UNS N08904 Heavy Hex Nuts

- Stainless Steel 904L Heavy Hex Nuts

- ASME SA193 Stainless Steel 904L Heavy Hex Nut

- Stainless Steel 904L Heavy Hex Nut Supplier

- Stainless Steel 904L Heavy Hex Nut Stockist

- SUS 904L Heavy Hex Nut

- 1.4539 Heavy Hex Nuts

- 904L Stainless Heavy Hexagon Nut

- AISI 904L Heavy Hexagon Nuts Exporter

- ASTM A193 Stainless Steel 904L Heavy Hex Nut

SS 904L Flange Nut

- SS 904L Hex Flange Nut

- Stainless Steel 904L Flange Nut Supplier

- AISI 904L Hexagon Flange Nut Exporter

- Stainless Steel 904L Hex Flange Nuts

- 1.4539 Flange Nut

- ASTM A193 Stainless Steel 904L Flange Nut

- ASME SA193 Stainless Steel 904L Flange Nut

- Stainless Steel 904L Flange Nut Manufacturer

- UNS N08904 Flange Nuts

- SUS 904L Flange Hex Nut

- 904L Stainless Hexagon Flange Nut

- Stainless Steel 904L Flange Nut Stockist

SS 904L Hex Weld Nut

- SUS 904L Weld Hex Nut

- 904L Stainless Hexagon Weld Nut

- ASTM A193 Stainless Steel 904L Weld Nut

- 1.4539 Hex Weld Nut

- Stainless Steel 904L Weld Nut Manufacturer

- Stainless Steel 904L Hex Weld Nuts

- Stainless Steel 904L Weld Nut Supplier

- UNS N08904 Hex Weld Nuts

- Stainless Steel 904L Weld Nut Stockist

- AISI 904L Hexagon Weld Nut Exporter

- SS 904L Hex Weld Nut

- ASME SA193 Stainless Steel 904L Weld Nut

SS 904L Hex Coupling Nut

- AISI 904L Hexagon Coupling Nut Exporter

- ASTM A193 Stainless Steel 904L Coupling Nut

- 904L Stainless Hexagon Coupling Nut

- SUS 904L Coupling Hex Nut

- 1.4539 Hex Coupling Nut

- ASME SA193 Stainless Steel 904L Coupling Nut

- UNS N08904 Hex Coupling Nuts

- Stainless Steel 904L Coupling Nut Stockist

- Stainless Steel 904L Coupling Nut Manufacturer

- Stainless Steel 904L Coupling Nut Supplier

- SS 904L Hexagonal Coupling Nut

- Stainless Steel 904L Hex Coupling Nuts

SS 904L Hex Jam Nut

- SUS 904L Jam Hex Nut

- Stainless Steel 904L Jam Nut Stockist

- Stainless Steel 904L Jam Nut Supplier

- 1.4539 Hex Jam Nut

- AISI 904L Hexagon Jam Nut Exporter

- ASTM A193 Stainless Steel 904L Jam Nut

- Stainless Steel 904L Jam Nut Manufacturer

- SS 904L Heavy Hex Jam Nut

- ASME SA193 Stainless Steel 904L Jam Nut

- UNS N08904 Hex Jam Nuts

- Stainless Steel 904L Hex Jam Nuts

- 904L Stainless Hexagon Jam Nut

WE MANUFACTURE Stainless Steel 904L Hex Nuts AS PER INTERNATIONAL STANDARDS & SPECIFICATIONS. 904L SS Hex Nut MANUFACTURERS IN INDIA, CUSTOM SIZES SS 904L Hex Jam Nuts, Panel Hex Nuts, Weld Hex Nut CAN BE PRODUCED AS PER CLIENT DRAWING.

- American Standard (ANSI/ASME/AWWA)

- German Standard (DIN)

- European Standard (EN)

- Japanese Standard (JIS)

- British Standard (BS)

- MSS Standard (MSS-SP)

- Petroleum Standard (API)

- Russian Standard (GOST)

- South African Standard (SABS / SANS)

- Hot Dipped Galvanizing

- Phosphate

- Teflon

- PTFE Coated

- Xylon

- Zinc Phosphate

- Manganese Phosphate

- Zinc Electro Plating

- ZAC (Zinc Aluminum Flake Coating)

Stainless Steel 904L Hex Nut Dimensions Chart

Metric Hex Nut Dimensions

| DIA | M4 | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M45 | M48 | M52 |

| Pitch | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 |

| Across Flat (S) Max Min | 7 | 8 | 10 | 13 | 16 | 18 | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 |

| 6.78 | 7.78 | 9.78 | 12.73 | 15.73 | 17.73 | 20.67 | 23.67 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | |

| Thickness (M) MaxMin | 3.2 | 4.7 | 5.2 | 6.8 | 8.4 | 10.8 | 12.8 | 14.8 | 15.8 | 18 | 19.4 | 21.5 | 23.8 | 25.6 | 28.7 | 31 | 33.4 | 34 | 36 | 38 | 42 |

| 2.9 | 4.4 | 4.9 | 6.44 | 8.04 | 10.37 | 12.1 | 14.1 | 15.1 | 16.9 | 18.1 | 20.2 | 22.5 | 24.3 | 27.4 | 29.4 | 31.8 | 32.4 | 34.4 | 36.4 | 40.4 | |

| Across corners (E) Min | 7.66 | 8.79 | 11.05 | 14.38 | 17.77 | 20.03 | 23.35 | 26.75 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | 76.95 | 82.6 | 88.25 |

| Minor Dia at thread (min) | 3.242 | 4.134 | 4.917 | 6.647 | 8.376 | 10.106 | 11.835 | 13.835 | 15.294 | 17.294 | 19.294 | 20.752 | 23.752 | 26.211 | 29.211 | 31.67 | 34.67 | 37.129 | 40.129 | 42.587 | 46.587 |

| Minor Dia at thread (max) | 3.422 | 4.334 | 5.153 | 6.912 | 8.676 | 10.441 | 12.210 | 14.210 | 15.744 | 17.774 | 19.774 | 21.252 | 24.252 | 26.771 | 29.771 | 32.27 | 35.27 | 37.799 | 40.799 | 43.297 | 47.297 |

All dimensions in mm

| DIA | M16 | M20 | M22 | M24 | M27 | M30 | M36 |

| Pitch | 2 | 2.5 | 2.5 | 3 | 3 | 3.5 | 4 |

| Head Across Flat (B) Min | 26.16 | 33 | 35 | 40 | 45 | 49 | 58.8 |

| Head Across Flat (B) Max | 27 | 34 | 36 | 41 | 46 | 50 | 60 |

| Height (H) Min Max | 16.4 | 19.4 | 22.3 | 22.9 | 26.3 | 29.1 | 35 |

| 17.1 | 20.7 | 23.6 | 24.2 | 27.6 | 30.7 | 36.6 | |

| Across corners C min | 29.56 | 37.29 | 39.55 | 45.20 | 50.85 | 55.37 | 66.44 |

| Minor Dia at thread (min) | 14.235 | 17.694 | 19.694 | 21.202 | 24.252 | 26.761 | 32.270 |

| Minor Dia at thread (max) | 14.610 | 18.144 | 20.144 | 21.702 | 24.752 | 27.321 | 32.870 |

904L Stainless Steel Heavy Hex Nut Dimensions

| Nominal | Width Across Flats (F) | Width Across Corners (C) | Heavy Hex Nut Thickness (H) | |||||

|---|---|---|---|---|---|---|---|---|

| Size | Basic | Max | Min | Max | Min | Basic | Max | Min |

| 1 | 1 5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 63/64 | 1.012 | 0.956 |

| 1 1/2 | 2 3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 1 15/32 | 1.505 | 1.433 |

| 1 1/4 | 2 | 2.000 | 1.938 | 2.309 | 2.209 | 1 7/32 | 1.251 | 1.187 |

| 1 1/8 | 1 13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 1 7/64 | 1.139 | 1.079 |

| 1 3/4 | 2 3/4 | 2.750 | 2.662 | 3.175 | 3.035 | 1 23/32 | 1.759 | 1.679 |

| 1 3/8 | 2 3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 1 11/32 | 1.378 | 1.310 |

| 1 5/8 | 2 9/16 | 2.562 | 2.481 | 2.959 | 2.828 | 1 19/32 | 1.632 | 1.556 |

| 1 7/8 | 2 15/16 | 2.938 | 2.844 | 3.392 | 3.242 | 1 27/32 | 1.886 | 1.802 |

| 1/2 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 31/64 | 0.504 | 0.464 |

| 1/4 | 1/2 | 0.500 | 0.488 | 0.577 | 0.556 | 15/64 | 0.250 | 0.218 |

| 2 | 3 1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1 31/32 | 2.013 | 1.925 |

| 2 1/2 | 3 7/8 | 3.875 | 3.750 | 4.474 | 4.275 | 2 29/64 | 2.505 | 2.401 |

| 2 1/4 | 3 1/2 | 3.500 | 3.388 | 4.041 | 3.862 | 2 13/64 | 2.251 | 2.155 |

| 2 3/4 | 4 1/4 | 4.250 | 4.112 | 4.907 | 4.688 | 2 45/64 | 2.759 | 2.647 |

| 3 | 4 5/8 | 4.625 | 4.475 | 5.340 | 5.102 | 2 61/64 | 3.013 | 2.893 |

| 3 1/2 | 5 3/8 | 5.375 | 5.200 | 6.207 | 5.928 | 3 7/16 | 3.506 | 3.370 |

| 3 1/4 | 5 | 5.000 | 4.838 | 5.774 | 5.515 | 3 3/16 | 3.252 | 3.124 |

| 3 3/4 | 5 3/4 | 5.750 | 5.562 | 6.640 | 6.341 | 3 11/16 | 3.760 | 3.616 |

| 3/4 | 1 1/4 | 1.250 | 1.212 | 1.443 | 1.382 | 47/64 | 0.758 | 0.710 |

| 3/8 | 11/16 | 0.688 | 0.669 | 0.794 | 0.763 | 23/64 | 0.377 | 0.341 |

| 4 | 6 1/8 | 6.125 | 5.925 | 7.073 | 6.755 | 3 15/16 | 4.014 | 3.862 |

| 5/16 | 9/16 | 0.562 | 0.546 | 0.650 | 0.622 | 19/64 | 0.314 | 0.280 |

| 5/8 | 1 1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 39/64 | 0.631 | 0.587 |

| 7/16 | 3/4 | 0.750 | 0.728 | 0.866 | 0.830 | 27/64 | 0.441 | 0.403 |

| 7/8 | 1 7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 55/64 | 0.885 | 0.833 |

| 9/16 | 15/16 | 0.938 | 0.909 | 1.083 | 1.037 | 35/64 | 0.568 | 0.526 |

UNC Heavy Hex Nut Dimensions

| UNC Nut N/B | Max Across Corners | Min Across Corners | Max Thickness | Min Thickness | Max Across Flats | Max Across Flats |

|---|---|---|---|---|---|---|

| 1 | 47.7 | 45.6 | 25.7 | 24.3 | 41.3 | 40 |

| 1 1/2 | 69.6 | 66.6 | 38.2 | 36.4 | 60.3 | 58.4 |

| 1 1/4 | 58.6 | 56.1 | 31.8 | 30.1 | 50.8 | 49.2 |

| 1 1/8 | 53.2 | 50.8 | 28.9 | 27.4 | 46 | 44.6 |

| 1 3/4 | 80.6 | 77.1 | 44.7 | 42.6 | 69.9 | 67.6 |

| 1 3/8 | 64.2 | 61.4 | 35 | 33.3 | 55.6 | 53.8 |

| 1 5/8 | 75.2 | 71.8 | 41.5 | 39.5 | 65.1 | 63 |

| 1 7/8 | 86.2 | 82.3 | 47.9 | 45.8 | 74.6 | 72.2 |

| 1/2 | 25.6 | 24.6 | 12.8 | 11.8 | 22.2 | 21.6 |

| 2 | 91.6 | 87.6 | 51.1 | 48.9 | 79.4 | 76.8 |

| 2 1/2 | 113.6 | 108.6 | 63.6 | 61 | 98.4 | 95.2 |

| 2 1/4 | 102.6 | 98.1 | 57.2 | 54.7 | 88.9 | 86.1 |

| 2 3/4 | 124.6 | 119.1 | 70.1 | 67.2 | 108 | 104.4 |

| 3 | 135.6 | 129.6 | 76.5 | 73.5 | 117.5 | 113.7 |

| 3/4 | 36.7 | 35.1 | 19.3 | 18 | 31.8 | 30.8 |

| 3/8 | 20.2 | 19.4 | 9.6 | 8.7 | 17.5 | 17 |

| 5/8 | 31.2 | 29.8 | 16 | 14.9 | 27 | 26.2 |

| 7/16 | 22 | 21.1 | 11.2 | 10.2 | 19 | 18.5 |

| 7/8 | 42.2 | 40.4 | 22.5 | 21.2 | 36.5 | 35.4 |

| 9/16 | 27.5 | 26.3 | 14.4 | 13.4 | 23.8 | 23.1 |

ISO Heavy Hex Nut Dimensions

| ISO Nut NB | Across Corners | MAX Thickness | MIN Thickness | MAX Across Flats | MIN Across Flats |

|---|---|---|---|---|---|

| M 8 | 14.38 | 6.8 | 6.44 | 13 | 12.73 |

| M 10 | 17.77 | 8.4 | 8.04 | 16 | 15.73 |

| M 12 | 20.03 | 10.8 | 10.37 | 18 | 17.73 |

| M 14 | 23.35 | 12.8 | 12.1 | 21 | 20.67 |

| M 16 | 26.75 | 14.8 | 14.1 | 24 | 23.67 |

| M 18 | 29.56 | 15.8 | 15.1 | 27 | 26.16 |

| M 20 | 32.95 | 18 | 16.9 | 30 | 29.16 |

| M 22 | 37.29 | 19.4 | 18.1 | 34 | 33 |

| M 24 | 39.55 | 21.5 | 20.2 | 36 | 35 |

| M 27 | 45.2 | 23.8 | 22.5 | 41 | 40 |

| M 30 | 50.85 | 26.6 | 24.3 | 46 | 45 |

| M 33 | 55.37 | 28.7 | 27.4 | 50 | 49 |

| M 36 | 60.79 | 31 | 29.4 | 55 | 53.8 |

| M 39 | 66.44 | 33.4 | 31.8 | 60 | 58.8 |

| M 42 | 71.3 | 34 | 32.4 | 65 | 63.1 |

| M 45 | 76.95 | 36 | 34.4 | 70 | 68.1 |

| M 48 | 82.6 | 38 | 39.4 | 75 | 73.1 |

| M 52 | 88.25 | 42 | 40.4 | 80 | 78.1 |

| M 56 | 93.56 | 45 | 43.4 | 85 | 82.8 |

| M 60 | 99.21 | 48 | 46.4 | 90 | 87.8 |

| M 64 | 104.86 | 51 | 49.1 | 95 | 92.8 |

| M 68 | 110.51 | 54 | 52.1 | 100 | 97.8 |

| M 72 x 6 | 116.16 | 58 | 56.1 | 105 | 102.8 |

| M 76 x 6 | 121.81 | 61 | 59.1 | 110 | 107.8 |

| M 80 x 6 | 127.46 | 64 | 62.1 | 115 | 112.8 |

Hex Nuts Grade Markings

| Hex Nuts Grade Identification Marking | Hex Nuts Specification | Nominal Size ub Inches | Hex Nuts Proof Load Stress ksi | Hardness Rockwell | |

| Min | Max | ||||

| ASTM A194 – Grade 1 | 1/4 thru 4 | 130 | B70 | – | |

| ASTM A194 – Grade 2 | 1/4 thru 4 | 150 | 159 | 352 | |

| ASTM A194 – Grade 2H | 1/4 thru 4 | 175 | C24 | C38 | |

| ASTM A194 – Grade 2HM | 1/4 thru 4 | 150 | 159 | 237 | |

| ASTM A194 – Grade 4 | 1/4 thru 4 | 175 | C24 | C38 | |

| ASTM A194 – Grade 7 | 1/4 thru 4 | 175 | C24 | C38 | |

| ASTM A194 – Grade 7M | 1/4 thru 4 | 150 | 159 | 237 | |

Stainless Steel 904L Hex Nut Popular Head Style

Weight Chart Of Stainless Steel 904L Hex Nuts

| Size | Hex Finished Nut | Heavy Hex Nut | Square Nut | Hex Finished Jam Nut |

|---|---|---|---|---|

| ¼” | 0.007 | 0.013 | ||

| 3/8” | 0.029 | 0.031 | 0.040 | |

| ½” | 0.038 | 0.065 | 0.057 | 0.027 |

| 5/8” | 0.073 | 0.119 | 0.049 | 0.108 |

| ¾” | 0.119 | 0.193 | 0.077 | 0.154 |

| 7/8” | 0.190 | 0.297 | 0.120 | 0.245 |

| 1” | 0.283 | 0.425 | 0.177 | 0.363 |

| 1 1/8” | 0.403 | 0.592 | 0.247 | 0.525 |

| 1 ¼” | 0.543 | 0.786 | 0.361 | 0.706 |

| 1 3/8” | 0.730 | 1.020 | 0.479 | 0.945 |

| 1 ½” | 0.943 | 1.310 | 0.609 | 1.220 |

| 1 5/8” | 1.620 | 0.916 | ||

| 1 ¾” | 1.510 | 2.040 | 1.000 | |

| 1 7/8” | 2.410 | 1.340 | ||

| 2” | 2.240 | 2.990 | 1.400 | |

| 2 1/8” | 3.350 | |||

| 2 ¼” | 4.200 | |||

| 2 ½” | 5.640 | |||

| 2 ¾” | 7.390 | |||

| 3” | 9.500 | |||

| 3 ¼” | 11.940 | |||

| 3 ½” | 15.260 | |||

| 3 ¾” | 18.120 | |||

| 4” | 21.830 |

Stainless Steel 904L Hex Nuts Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 904L | min. | – | – | – | – | – | 19.0 | 4.00 | 23.00 | 0.10 |

| max. | 0.20 | 2.00 | 1.00 | 0.045 | 0.035 | 23.0 | 5.00 | 28.00 | 0.25 | |

904L Stainless Steel Hex Nuts Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 904L | 490 | 220 | 35 | 70-90 typical | – |

We are One Of The Most Trusted Supplier Of 904L Stainless Steel Hex Nut in India. For final SS 904L Heavy Hex Nut Price List

Please Call on +91 80809 86211 or drop an E-Mail : info@hexforgeinc.com

Ready Stock Of Stainless Steel 904L Hex Nuts

- 904L Stainless Steel Flange Nut

- Stainless Steel 904L Industrial Hex Nut

- Stainless Steel 904L Eye Nuts

- SS 904L Heavy Duty Nut

- Stainless Steel 904L Lock Nuts

- Stainless Steel 1.4539 Hex Nuts

- ASTM A193 SS 904L Cage Nut

- ASTM A193 Stainless Steel 904L Hex Nut

- Stainless Steel 904L Dome Nuts Manufacturer

- Stainless Steel 904L Metric Hex Nuts

- 904L Stainless Steel Square Nut

- ASTM A193 Stainless Steel 904L Heavy Hex Nut

- Stainless Steel UNS N08904 Hex Nut

- Stainless Steel 904L Wing Nut

- 904L Stainless Steel Hex Flanged Nuts

- Stainless Steel 904L Heavy Hex Head Nut

- SS 904L Insert Rivet Nut Manufacturer

- SS 904L Long Hex Nut

- 904L SS Hex Nuts Stock At Best Price

- Stainless Steel 904L Self Clinch Nut

- Stainless Steel 904L Industrial Hex Nuts

- SS 904L Hex Head Nuts

- SS 904L Slotted Hex Nuts Stockist

- Stainless Steel 904L Long Hex Nut

- 904L Stainless Steel M8 Hex Nut

- SS 904L Thin Hex Nuts

- Stainless Steel 904L Insert Nut

- UNS N08904 Heavy Hex Nut

People also Search for 904L SS Hex Nuts

We Export Stainless Steel 904L Hex Nuts Across the Globe

MIDDLE EAST

| AFRICA

| EUROPE

| ASIA

|

Domestic Supply Stainless Steel 904L Hex Nuts

| Bengaluru | Mumbai | Chennai | Hyderabad | Kolkata | Pune |

| New Delhi | Ahmedabad | Jaipur | Surat | Salem | Gandhinagar |

| Bhiwandi | Tiruppur | Sivakasi | Jamnagar | Thiruvananthapuram | Rajahmundry |

| Bhubaneswar | Vijaywada | Firozabad | Bokaro Steel City | Rajkot | Bharuch |

| Panna | Raipur | Cochin | Ludhiana | Panipat | Durgapur |

| Peenya | Pimpri-Chinchwad | Channapatna | Kharagpur | Nashik | Bareilly |

| Varanasi | Haldia | Rourkela | Bangalore | Moradabad | Indore |

| Visakhapatnam | Trivandrum | Pithampur | Dibrugarh | Angul | Gwalior |

| Coimbatore | Kannur | Nagpur | Vadodara | Rudrapur | Noida |

| Agra | Bhagalpur | Jamshedpur | Bhilai | Lucknow | kanpur |

| Thane | Bhopal | Navi Mumbai | Vasai | Bikaner | Maharashtra |

- Stainless Steel

- Duplex Steel

- Super Duplex Steel

- Inconel

- Monel

- Hastelloy

- Titanium

- Cupro Nickel

- Copper

- Alloy 20

- Carbon Steel

- Aluminium Bronze

- Silicon Bronze

- Phosphorous Bronze

- Corten Steel

- Countries

- City